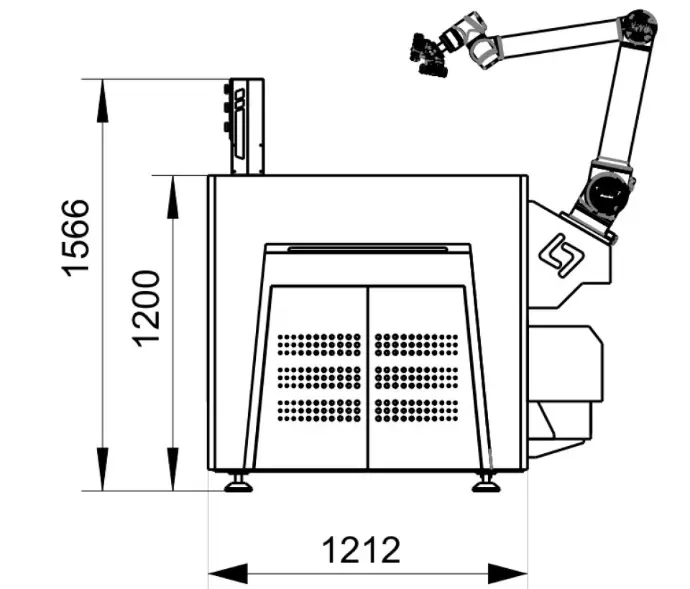

RI CNC tending collaborative station

RI CNC tending collaborative station

A CNC tending station integrates a collaborative robot with intelligent grippers, machine interfaces, and safety features to automate part-handling operations. Unlike traditional industrial robots, collaborative stations are built to work safely alongside human operators — without fencing — making them ideal for dynamic production environments.

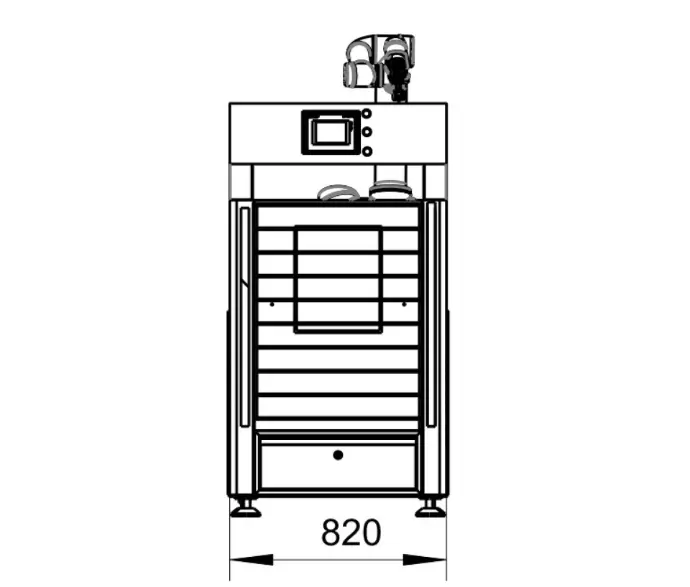

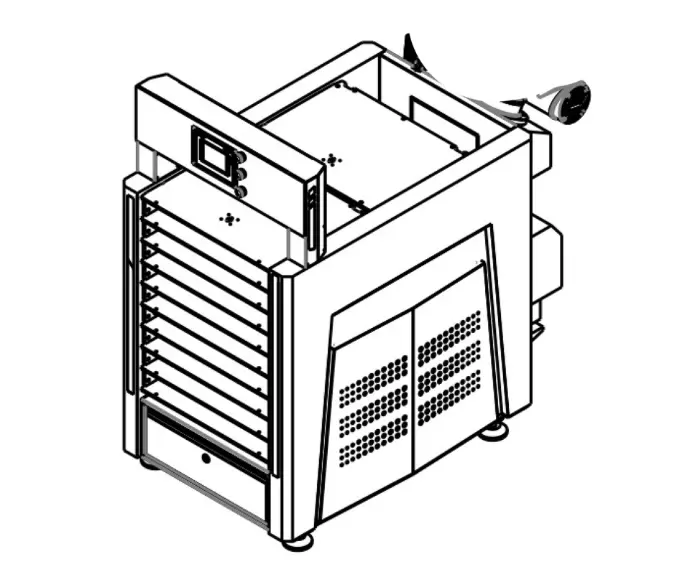

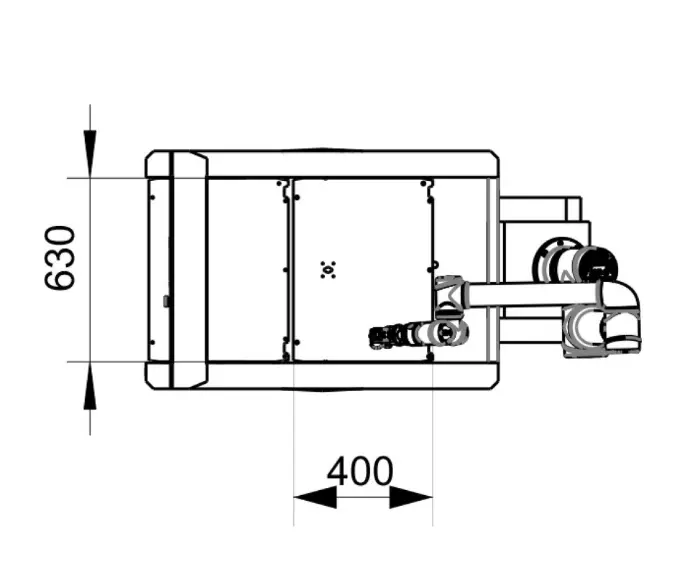

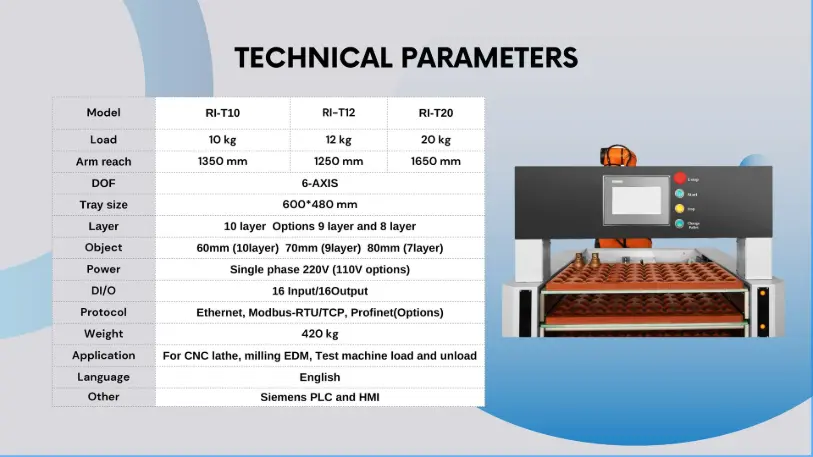

RI CNC tending collaborative station includes:

- Collaborative robot with built-in force sensing

- An intelligent warehouse system controlled by PLC and HMI interface, the management and access of parts is done using a high-precision 2-axis system

- Machine interface modules for seamless communication with CNCs (via I/O or industrial protocols)A workstation frame or mobile base that allows quick deployment

Key Advantages

24/7 Operation – Enables lights-out manufacturing with continuous, unattended production.

Precision & Consistency – Delivers repeatable results, eliminating manual errors.

Rapid Deployment – Easy to program and adapt for small batches or frequent changeovers.

Safe Collaboration – Built-in sensors allow safe interaction with human workers, no cages needed.

Quick ROI – Payback typically within 12–18 months through labor savings and higher uptime.

RI CNC tending collaborative station

Industry Applications of Machine Tending Robots

Machine tending robots are transforming industrial automation across multiple sectors by improving safety, precision, and throughput. Here's how key industries leverage this technology:

Automotive Industry

Robots streamline critical operations such as CNC machining, metal stamping, injection molding, and adhesive dispensing — boosting efficiency and consistency in vehicle and parts production.

Metalworking & Fabrication

In fabrication shops, robotic tending automates stamping, punching, bending, and cutting tasks, ensuring high accuracy, reduced waste, and faster production cycles.

Plastics & Injection Molding

Robots are essential in injection molding lines, where they manage part placement and ejection with speed and precision, reducing cycle times and minimizing defects.

Aerospace & Defense

For high-precision parts, robotic tending ensures consistent loading and unloading, supporting tight tolerances and strict quality control in mission-critical applications.

Foundry & Casting

Designed to withstand extreme environments, these robots handle molten materials and high-temperature parts, enhancing operator safety and process reliability.

Why Invest in a RI CNC tending collaborative station?

Implementing a CNC Tending Collaborative Station is not just about automation — it’s about future-proofing your production. Whether you’re looking to scale output, optimize shift coverage, or improve precision, collaborative automation delivers flexibility and performance with minimal integration effort.

It bridges the gap between manual labor and full industrial automation — empowering manufacturers of any size to compete in today’s high-mix, fast-paced market.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.