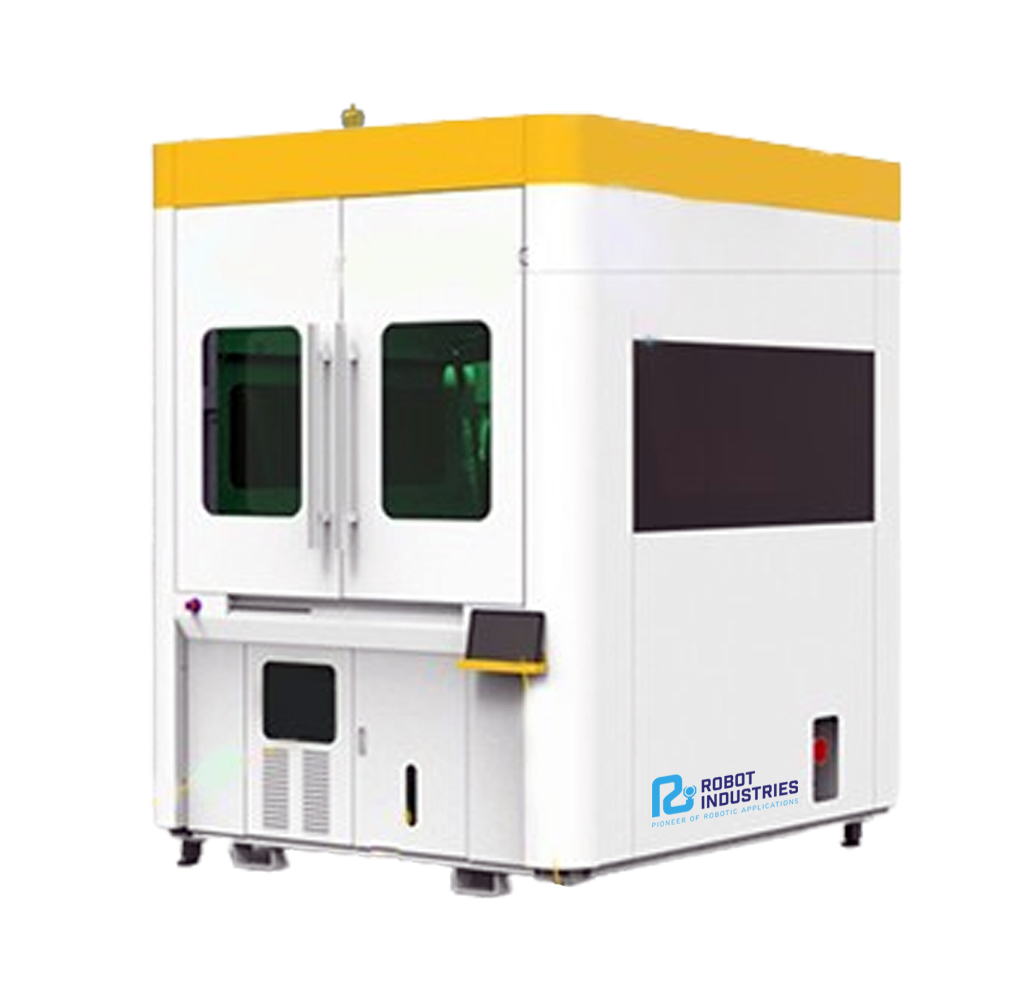

RI WD Collaborative closed welding station

RI WD Collaborative closed dual welding station

Single Station Welding System with Protective Shell – Robot Industries

The ideal solution for precision welding in environments with strict safety and air quality requirements. The Single Station System with Shell from Robot Industries provides a fully enclosed workspace designed to minimize risk and maintain clean, controlled conditions.

With standard dimensions of 1.7 x 1.9 x 2.4 meters (customizable on request), the unit features double-door access, arc light filtering observation windows, and a high-performance smoke and dust extraction system.

The OD16-grade safety cabin ensures maximum protection for high-risk welding operations. A panoramic viewing design eliminates blind spots, while multiple safety interlocks guarantee secure and stable operation.

Key Benefits:

- Fully enclosed cabin for safe, high-precision welding

- Ergonomic interface for comfortable, intuitive operation

- Efficient air filtration and welding fume removal

- Reinforced structure for all-around operator protection

- Real-time visibility through heat-resistant observation windows

Perfect for industries focused on worker safety, environmental protection, and consistent welding quality.

Fully Enclosed Welding Booth: A sealed, single-operator station designed for high-precision welding in controlled environments.

Double-Door Entry + Arc Light Filtering: Minimizes light pollution and supports safe observation during welding processes.

High-Efficiency Dust and Smoke Removal: Meets strict environmental standards, maintaining clean air in enclosed workspaces.

OD16-Grade Safety Cabin: Delivers superior protection, ensuring zero-risk operation during hazardous welding tasks.

Panoramic Observation Design: No blind spots. Full visibility throughout the process for enhanced quality control and operational oversight.

Advanced Safety Interlocks: Built-in redundancies and emergency systems ensure immediate shutdown and operator protection.

The RI COBOT welding collaborative robot workstation perfectly integrates collaborative robot technology with intelligent welding processes, bringing a revolutionary change to the manufacturing industry. It provides a new, efficient, flexible, and safe automated welding solution, helping enterprises reach new heights in intelligent manufacturing.

Standard

Intelligent welding system controller, Special welding gun (with 5-meter cable), Wire feeder (with 5-meter cable), Six axis collaborative robot, Welding power source, Special control board, Portable permanent magnet base, Multi joint panel bracket, Water cooler

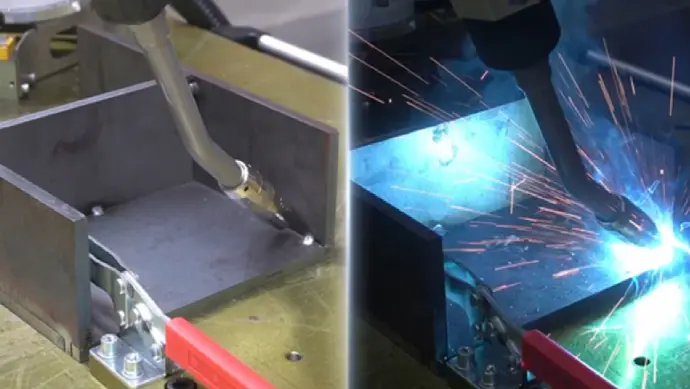

FULL WELD TYPE IS UNIVERSAL

Simple and complex welding is easy to deal with!

- Supports a variety of types such as straight weld, arc weld, corner weld and splicing weld.

- It can be combined with a variety of oscillating welding methods to easily deal with various welding tasks.

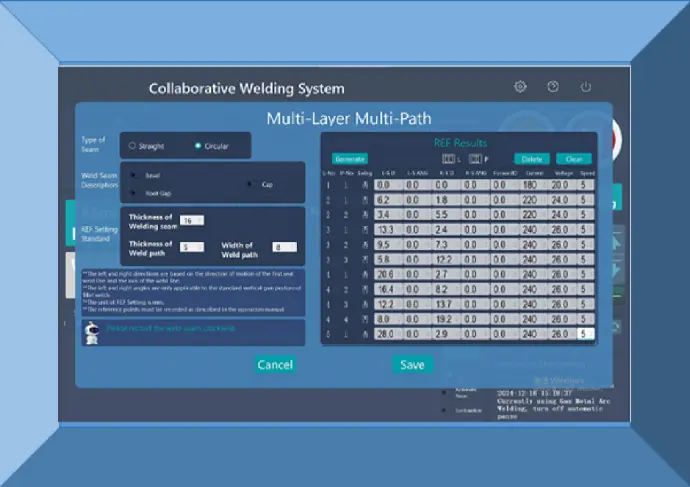

AUTOMATIC INTELLIGENT WELDING SEAM ARRANGEMENT

Parameters are customizable

- Support automatic layering planning for straight lines/arcs/fillet welds.

- Supports multi-layer and multi pass welding of straight line welds, circular arc welds, and groove welds.

- Customizable weld spacing, swing amplitude, bevel angle, etc.

- Supports automatic and manual routing of multi-layer and multi pass welds.

- Support intelligent weld bead planning through key parameters.

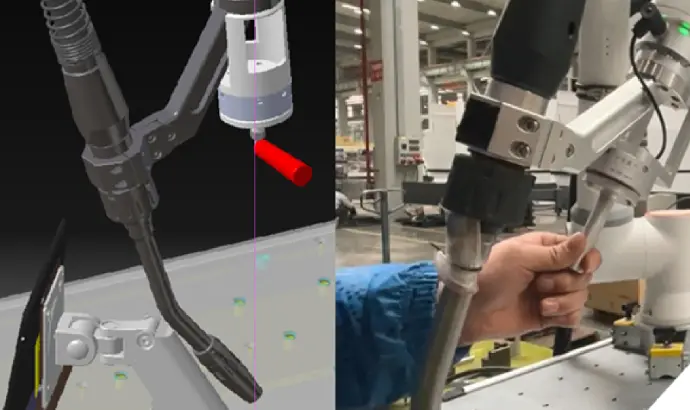

SIX DIMENSION TECHNOLOGY

Foldable handle

- Equipped with high resolution six-dimensional force/torque sensor (positioning accuracy up to ±0.05mm).

- Zero programming drag and teach is realized. The operator can directly pull the robot arm to complete trajectory calibration through the foldable handle. It is used for welding complex surfaces and narrow Spaces.

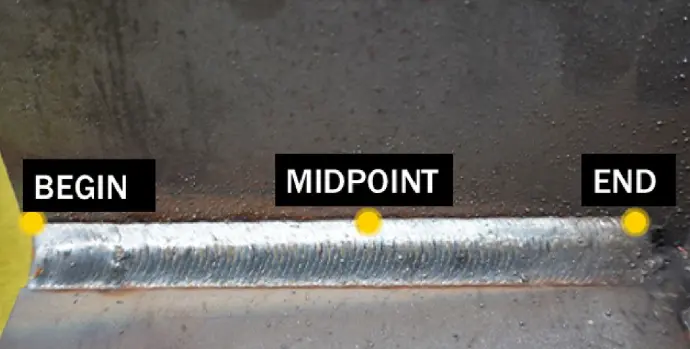

INTELLIGENT WELD PLANNING

The three-point positioning is used to overcome the welding of medium and thick plates, and the bevel error is compatible with strong.

GUN POSTURE SELF COMPENSATION TECHNOLOGY

Automatic Welding Gun Adjustment

The system automatically adjusts the welding gun's angle and offset for precise positioning.

Precision Control via Patented Algorithm

Original algorithm ensures optimal gun posture and offset, guaranteeing high-quality welding results.

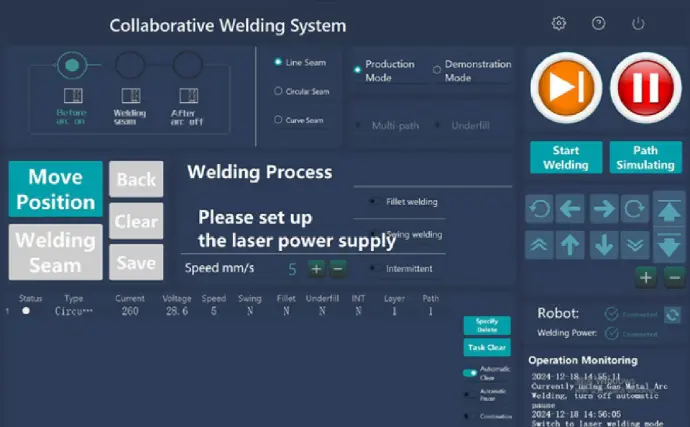

HUMAN COMPUTER COLLABORATIVE OPERATING SYSTEM

One-Click Standard Welding

Enable quick completion of small-batch repetitive welding tasks with just one click.

Standardization & Inheritance of Welding Processes

Establish standardized WPS (Welding Procedure Specifications) for effective management and utilization of welding processes.

WPS Process Library with Flexible Parameter

Built-in expert parameter library for materials like carbon steel, stainless steel, and aluminum alloy, offering reliable welding parameter references.

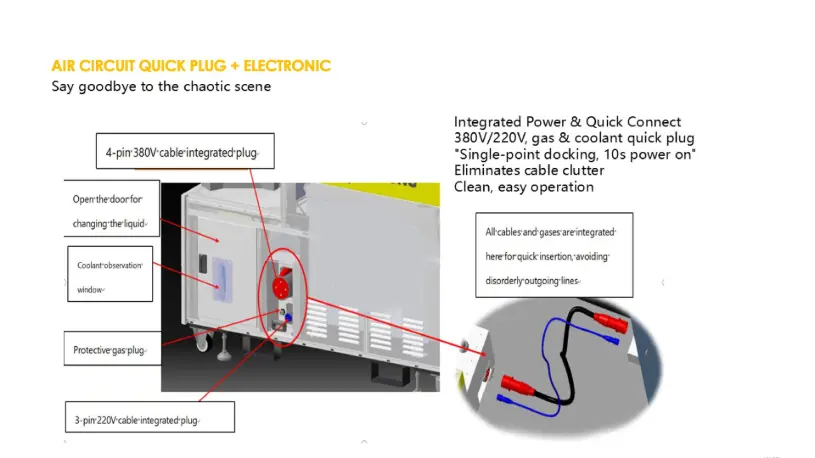

OD16 level safety cabin

- Arc protection: Double-sided explosion-proof observation windows, allowing for real-time monitoring of the welding process and timely understanding of the operation status.

- Smoke and dust purification system: Effectively eliminates welding smoke and dust, keeping the air in the welding room fresh.

- External emergency stop safety button: One click shutdown in case of emergency to ensure personnel safety.

Panoramic visualization design

Ergonomic Perspective: Optimized with a 15° tilt angle for the control panel, standing/sitting posture conforms to ergonomic design.

Welding machine status window: Built-in high-definition high-temperature resistant glass, real-time monitoring of arc stability and wire feeding mechanism action.

Coolant observation window: With scale markings and level sensor.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.