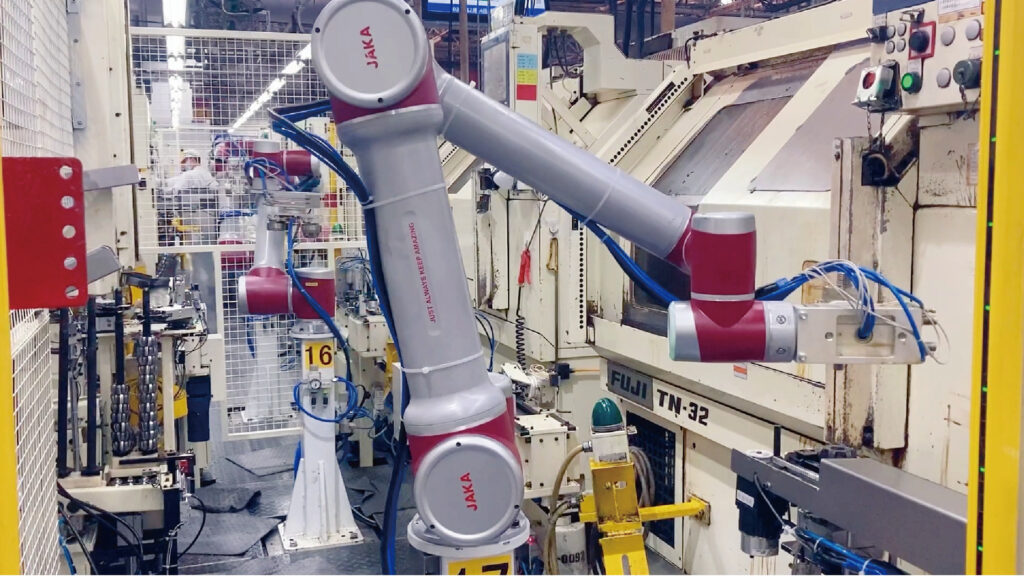

Pick and place Robotic Solution

Pick and Place tasks are those that involve picking and placing in a different place or position, whether they are parts, products or other elements or loads. These are common logistical tasks in factories, warehouses and industrial environments, which a robot can handle perfectly well as they are mechanical, repetitive and tedious. This is where pick and place robots come into their own.

Traditionally, static robotic arms are referred to as pick & place robots, but JAKA is a pioneer in autonomous mobile manipulation: it is a mobile platform that integrates a robotic arm. This means that the robot arm is no longer bound to a fixed, specific space, but can perform pick and place tasks in as many locations as required.

The

advantages of Pick & Place robots

for production processes are diverse, and derive, fundamentally, in two benefits: the reduction of production times and increase in the profitability of the same.

- Increased production rate

- Minimising errors in the production process

- 24/7 working shifts

- Increased production rate

- Increased accuracy

Pick and place robots offer several advantages as compared to using human workers for the same purpose. Some of these advantages are:

Speed: The speed of operation is one of the major reasons in favor of pick and place robots. These machines can lift a lot of objects at the same time that it would take a human worker to lift one object.

Productivity: Due to a higher speed of operation, a pick and place robot has higher productivity than human counterpart. This is why modern manufacturing environments are able to roll out a higher number of products, to increase production rates.

Uninterrupted Production: Human workers require breaks, which can lead to interruptions in the production line. Interruptions also occur during the change of shift of workers. However, robots do not require breaks and can work all day and night.

Consistency: Human labor always brings in the factor of human error. However, a pick and place robot will work on exact mathematical principles, so there are no errors and the end result is a consistent operation.

Safety: Lifting objects involves the risk factor of the object falling down on human workers and causing injuries. However, robots have no such risk, leading to higher safety in the workplace.

Return on Investment: Pick and place robots enables companies to minimize running costs by incurring a small initial investment. There are no salaries and no benefits to pay. This results in a higher return on investment in the manufacturing processes.

Throughput: Pick and place robots result in a higher throughput as they can move a lot of objects in a given time. As mentioned earlier, fast pick robots are capable of moving items at the rate of 300 skus per hour.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.