RI WD Collaborative closed dual welding station (hanging robot)

RI WD Collaborative closed dual welding station (hanging robot)

Configuration: inverted robot (2.7 x 1.9 x 2.4m) + top walking track

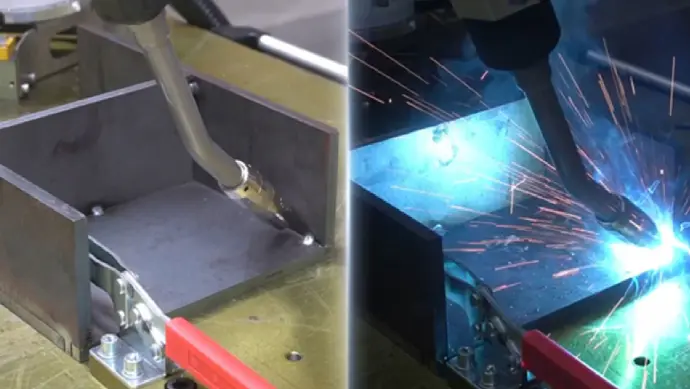

Scenario: large structural parts welding, multi-angle complex welds, workshop with limited ground space

Core advantage: Space master double working position inverted design, save space, suitable for complex workpiece welding.

Efficiency doubling: alternating human-machine operation to improve operation efficiency and increase the utilization rate of three-dimensional space by 40%

All-round welding: whether vertical, inclined or complex curved surface, stable output of high quality welding effect, no fear of tricky angles

FULL WELD TYPE IS UNIVERSAL

Simple and complex welding is easy to deal with!

- Straight Seam Welding

- Arc & Circular Welding

- Fillet Welding (corner joints)

- Splicing & Overlap Welding

- Custom waveform configurations

- Adjustable oscillation patterns

- Intelligent bead control

Supported Weld Types:

Oscillation Technology Features:

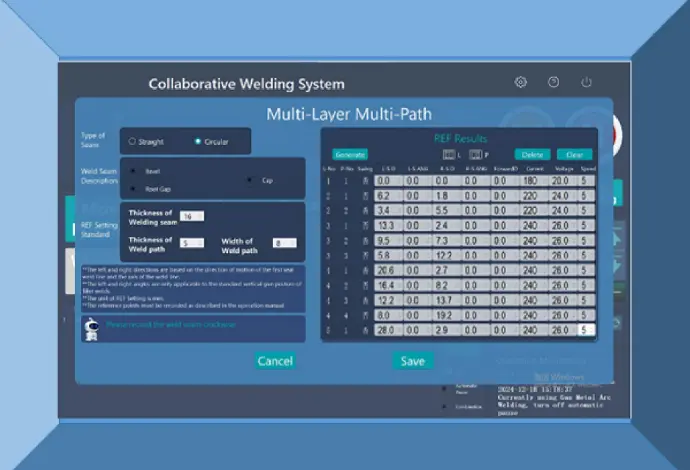

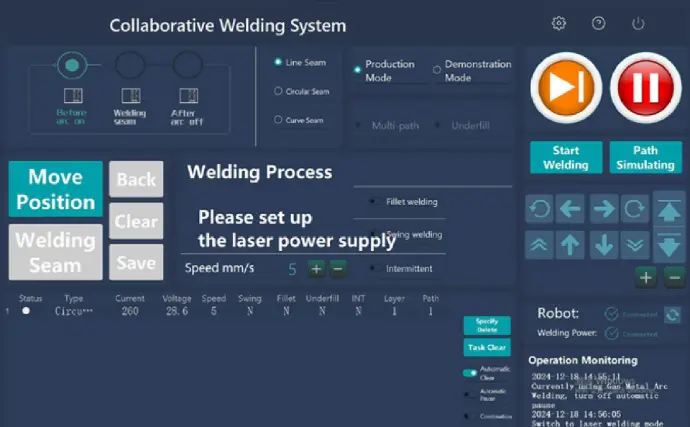

AUTOMATIC INTELLIGENT WELDING SEAM ARRANGEMENT

- Automated layering for:

- Straight seams

- Arc/circular welds

- Fillet joints

- Groove welds

- Custom parameters: spacing, oscillation, bevel angle

- AI-powered bead planning

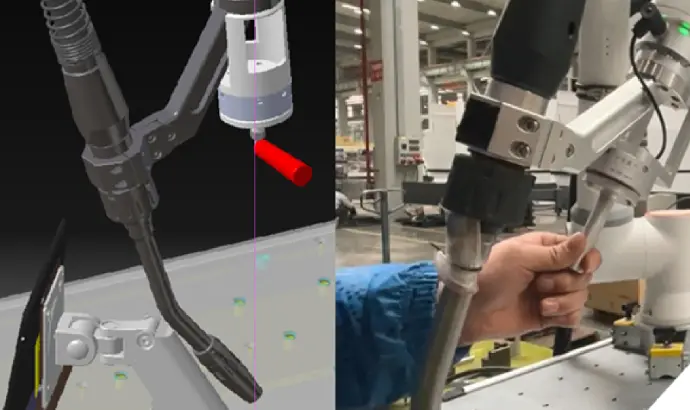

SIX DIMENSION TECHNOLOGY

Core Technology:

- 6-Axis F/T Sensor: ±0.05mm positioning accuracy

- Real-time force feedback for micro-adjustments

Zero-Programming Operation:

- Drag & Teach Functionality:

- Direct trajectory calibration via foldable handle

- Operator-guided robotic arm movement

- Instant path setup without coding

Critical Applications:

- Complex curved surface welding

- Narrow-space joint access

- Confined area operations

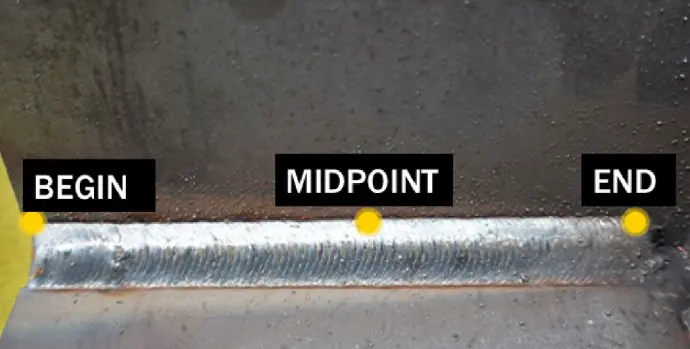

INTELLIGENT WELD PLANNING

- Three-point positioning overcomes medium/thick plate welding challenges

- Automatic bevel error compensation ensures consistent quality

GUN POSTURE SELF COMPENSATION TECHNOLOGY

- Real-time automatic gun angle/offset adjustment

- Patented algorithm guarantees ±0.05mm positioning

HUMAN COMPUTER COLLABORATIVE OPERATING SYSTEM

- One-Click Standard Welding: Rapid small-batch production

- WPS Standardization: Create/reuse certified welding procedures

- Material-Specific Libraries: Pre-optimized parameters for:

- Carbon steel

- Stainless steel

- Aluminum alloys

OD16 level safety cabin

- Arc protection: Double-sided explosion-proof observation windows, allowing for real-time monitoring of the welding process and timely understanding of the operation status.

- Smoke and dust purification system: Effectively eliminates welding smoke and dust, keeping the air in the welding room fresh.

- External emergency stop safety button: One click shutdown in case of emergency to ensure personnel safety.

Panoramic visualization design

Ergonomic Perspective: Optimized with a 15° tilt angle for the control panel, standing/sitting posture conforms to ergonomic design.

Welding machine status window: Built-in high-definition high-temperature resistant glass, real-time monitoring of arc stability and wire feeding mechanism action.

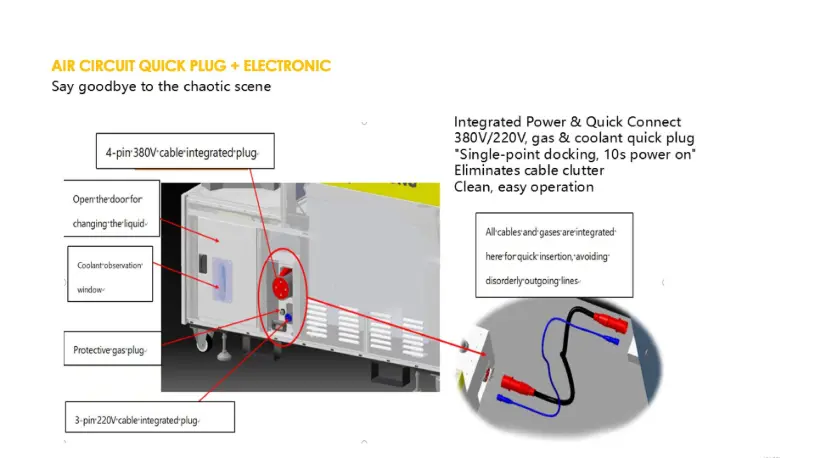

Coolant observation window: With scale markings and level sensor.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.