RI WD 3D FreeTeach Industrial Welding Station

RI WD 3D FreeTeach Industrial Welding Station

The Future of Robotic Welding – No Manual Programming Required

In today’s industrial environment, where skilled labor shortages, rising costs, and increasing quality demands challenge manufacturers, intelligent welding automation is no longer optional.

The RI WD 3D FreeTeach Industrial Welding Station redefines robotic welding by completely eliminating traditional manual programming and transforming welding into a fast, flexible, and efficient process.

What is the RI WD 3D FreeTeach Industrial Welding Station

The RI WD 3D FreeTeach is a fully automated industrial welding station equipped with 3D vision technology and intelligent welding path planning software.

Unlike traditional “teach & repeat” robotic systems, it:

- requires no manual welding path programming

- automatically recognizes part geometry

- autonomously generates the optimal welding path

- quickly adapts to different workpieces

The result is a dramatic reduction in setup time and consistent welding quality, even for complex parts.

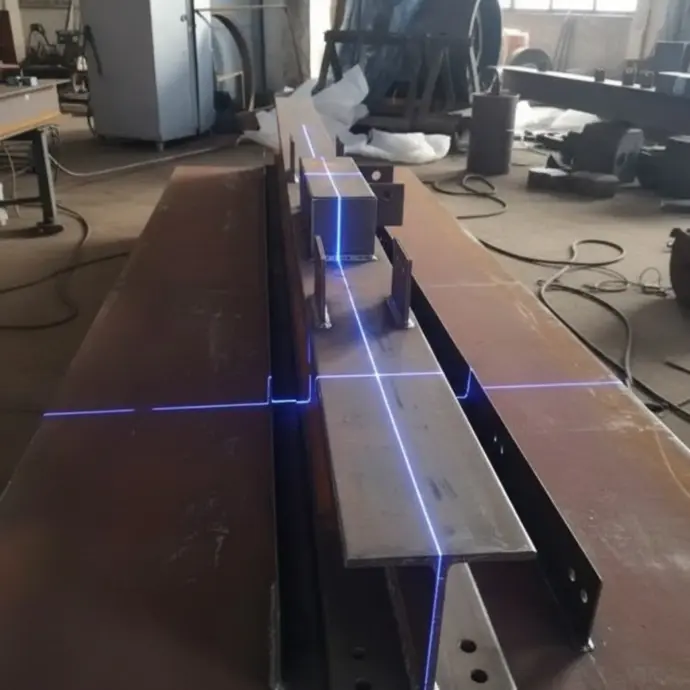

FreeTeach Technology – Teach-Free Welding

The key innovation of the RI WD station is FreeTeach (Teach-Free Welding) technology.

The operator no longer needs to manually teach the robot. The system:

- scans the part using 3D vision

- automatically detects welding seams

- calculates optimal welding parameters (speed, current, angle)

- performs the weld with high precision

This approach makes robotic welding accessible even for companies without dedicated robot programmers.

Key Features

- 3D vision system for automatic part recognition

- Autonomous welding path planning

- High precision and repeatability (±0.02 mm)

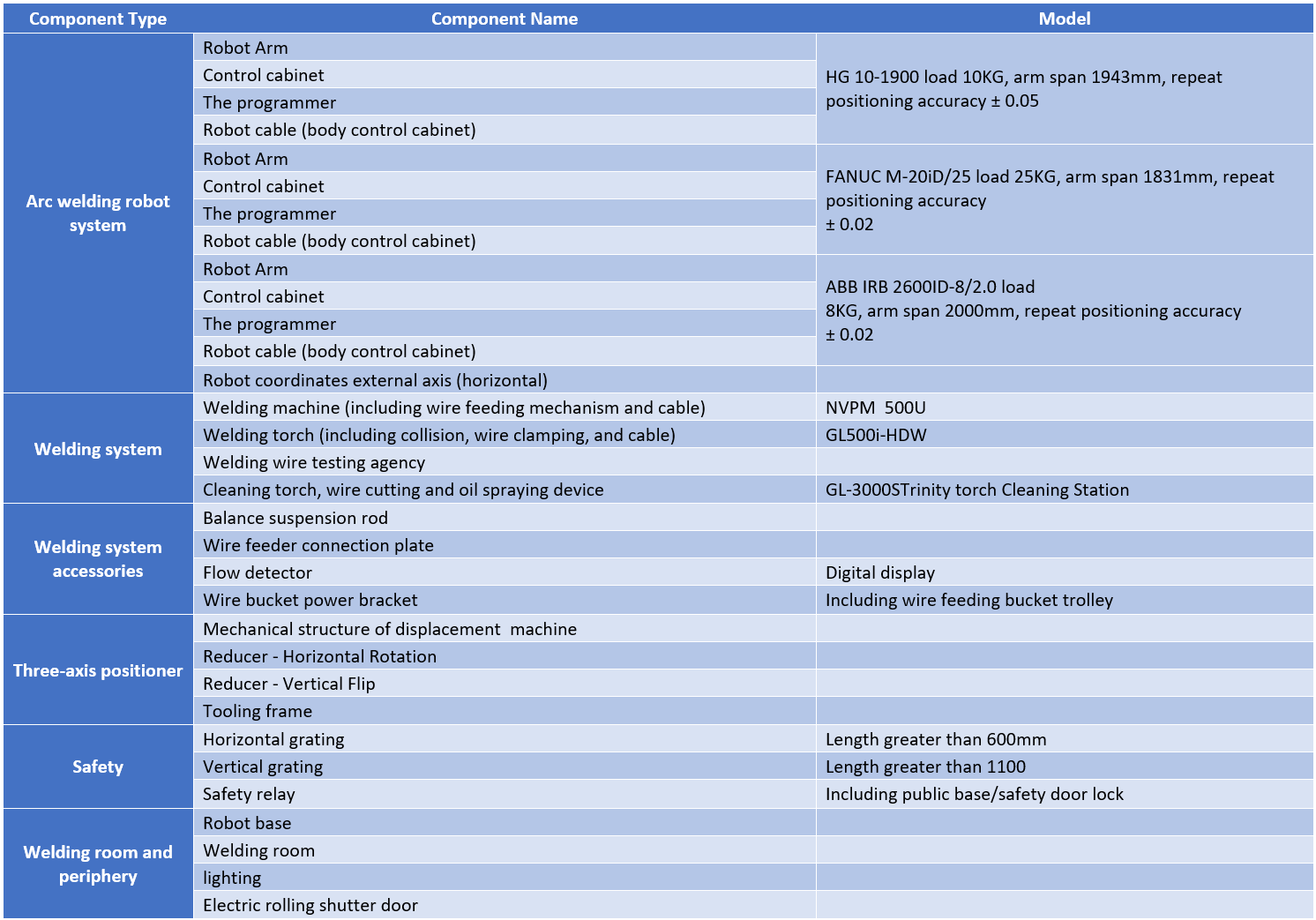

- Compatibility with multiple industrial robots (RI, FANUC, ABB, Estun, etc.)

- MIG/MAG welding support (350A – 500A)

- Advanced welding functions: corner welding, circular welding, multi-pass welding, weaving

- Automatic torch cleaning system

Real Production Benefits

Reduced Setup Time

Fast configuration for new parts enables quick changeovers between different production batches.

Consistent Welding Quality

Eliminating manual programming ensures uniform, repeatable welds that meet industrial standards.

Maximum Flexibility

Ideal for small and medium batch production, where part geometry changes frequently.

Lower Operating Costs

Reduced dependence on highly skilled welders and fewer defects result in a fast return on investment.

Application Areas

The RI WD 3D FreeTeach Industrial Welding Station is ideal for:

- metal structure fabrication

- automotive components and subassemblies

- heavy machinery and industrial equipment

- customized production and special projects

Why Choose RI WD 3D FreeTeach

✔️ True automation without manual programming

✔️ Fast integration into existing production lines

✔️ Increased productivity and weld quality

✔️ A future-ready solution for modern industry

The RI WD 3D FreeTeach Industrial Welding Station is not just a welding system—it is an intelligent automation platform that fundamentally changes how industrial welding is performed.

It is the ideal solution for companies aiming to stay competitive, efficient, and ready for the future of manufacturing.

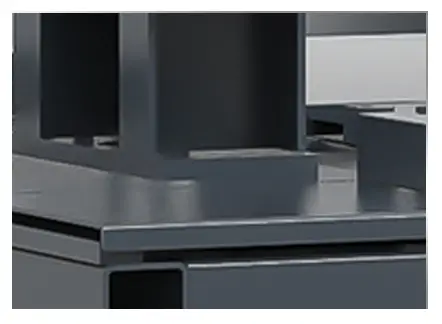

Front & Rear Double-Station

T-type workstation adopts left and right double-station arrangement, the robot (welding) and the ope-rator (loading and unloading) work alternately between the two stations. This way can avoid or reduce the robot waiting time and improve productivity.

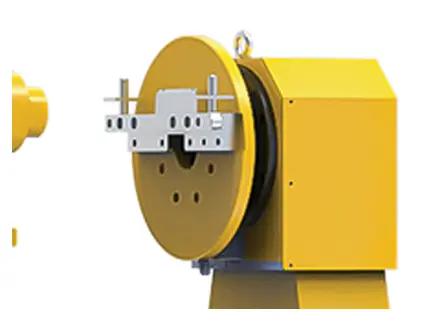

Omni-Directional Welding

The workstation is equipped with an external axis vertical turnover indexer, which can coordinate the robot to complete the welding of weld seams in all angular directions.

Modular Sizing

Single workstation is suitable for the production of products with length less than 1.8m and width less than 1.5m: Double workstation is suitable for the production of products with length less than 3m and wid-th less than 1.5m.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.